Various fluids can be differentiated by their fluid properties, some of the basic fluid properties are density, specific weight, specific gravity, viscosity & specific volume. Let's take a look at the properties of fluids one by one in detail. Fundamental knowledge of fluid properties is very essential to learn Fluid Mechanics (FM) subject.

Properties of fluid

- Density or Mass Density

- Specific Weight or Weight Density

- Specific Volume

- Specific Gravity

- Viscosity

1. Density or Mass Density

- The density of the fluid can be defined as a ratio of the mass of fluid to the volume of fluid. Hence it can be call mass per unit volume.

- It is represented by a symbol ⍴ (rho) and the SI unit of density is kg/m³.

- Mathematically,

- The density of water is taken as 1000 kg/m³ or 1 g/cm³.

- The density of a liquid is considered as constant with the variation of pressure and temperature.

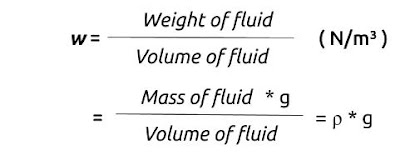

2. Specific Weight or Weight Density

- The specific weight of fluid can be defined as the ratio of the weight of the fluid to the volume of fluid.

- It is represented by w and also called weight density and the SI unit is N/m³.

- Mathematically,

- The value of specific weight or weight density of water is 9.81* 1000 N/m³.

3. Specific Volume

- The specific volume of fluid can be defined as the volume of the fluid occupied by a unit mass.

- Hence, it is reciprocal of density and it's SI unit is m³/kg.

- Mathematically,

4. Specific Gravity

- Specific gravity is defined as the ratio of the weight density of the fluid (or density) to the weight density (or density) of standard fluid.

- For liquid, water is taken as standard fluid.

- For gas, the air is taken as standard fluid.

- Specific gravity is also called relative density. as specific gravity is a ratio of two density, it is a dimensionless quantity and it is represented by S.

- Mathematically,

- Example: Density of Mercury is 13600 kg/m³, hence sp. gravity of mercury = 13.6

5. Viscosity

- Viscosity (or dynamic viscosity) is defined as the property of the fluid that offer resistance to the movement of one layer of fluid over another adjacent layer of fluid.

- Viscosity is represented by μ and its SI unit is N.s/m².

- For liquid, the viscosity of a fluid is due to inter-molecular attraction force.

- For gas, the viscosity of a fluid is due to the random motion of molecules.

- As per Newton's law of viscosity, shear stress between two fluid layers is proportional to the rate of angular deformation. Hence,

|

| Fig.-Velocity distribution near a solid boundary |

- Mathematically,

where, τ is shear stress between two layers of fluid, and μ is constant of proportionality and called viscosity.

- From the above equation, viscosity also defined as the shear stress required to produce a unit rate of shear strain.

- Another unit of viscosity is poise. 10 poise = 1 N.s/m².

Comments

Post a Comment